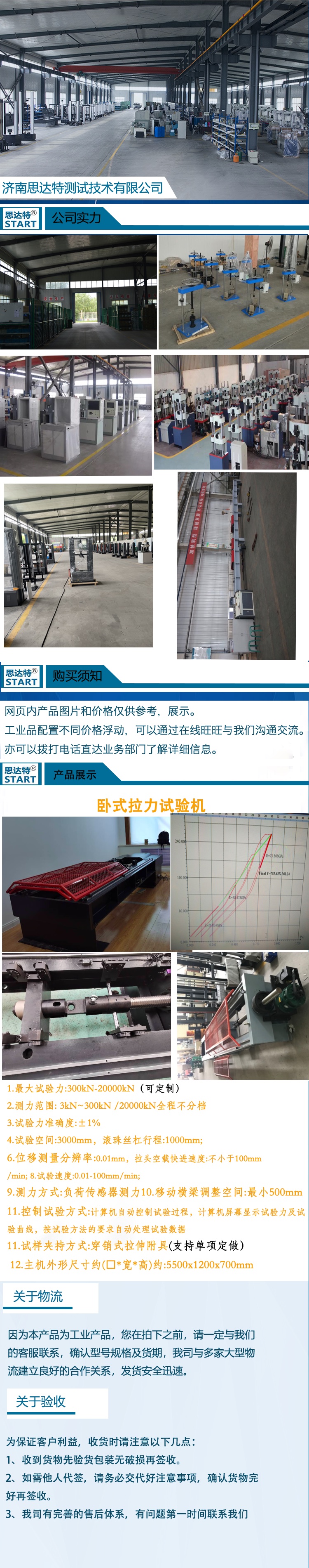

Horizontal Testing Machine

Horizontal tensile testing machine has the following characteristics:

Long specimen testing capability: The horizontal tensile testing machine is particularly suitable for tensile testing of long specimens and full-size specimens, capable of meeting the testing needs of large-sized samples.

Structural design: It usually adopts a steel plate welded frame structure to provide a stable testing platform, and has the function of a segmented moving crossbeam to adjust the test space.

Method of applying test force: A single rod double-action piston cylinder is used to apply the test force, ensuring accurate force application.

High-precision sensor: Equipped with a load sensor for measuring force to ensure the accuracy of the test force measurement.

Control system: It can be either a microcomputer display control or a microcomputer-controlled electro-hydraulic servo system, achieving automatic control of the test process and precise measurement of data.

Flexible technical parameters: The measurement range of the test force is wide, the measurement accuracy of the test force is high, the error of the displacement indication is small, and the stretching distance and cylinder stroke can be customized according to user requirements.

Safety protection: Equipped with safety measures such as mechanical limit protection, overload protection, overcurrent and leakage protection.

Software functions: Equipped with dedicated testing software for data collection, processing, and output of test reports.

Easy operation: The use of a fully digital LCD controller simplifies the human-machine interaction process, making the equipment easy to operate and the data accurate.

Curve analysis: It can create characteristic curves of material tests such as force-elongation, elongation-time, and can perform local amplification and analysis.

Maintenance function: It has an automatic maintenance stop function, such as automatic stop in case of specimen breakage, overload, or overcurrent.

Wide application range: Suitable for tensile performance testing of various metal materials, steel cables, chains, anchor chains, lifting straps, cables, etc.

Customizable test requirements: Users can output standard reports according to their own requirements and perform superimposed analysis of test curves in groups.

Main technical indicators:

Maximum test force: 2500kN (can be customized up to 5000kN)

Force measurement range: 40kN~2500kN, no sub-ranges throughout the range

Test force accuracy: ±1%

Test machine stretching space: 4000mm (customizable for extension and width)

Cylinder stroke: 1000mm

Displacement measurement resolution: 0.01mm

Fast approach speed of the head without load: not less than 100mm/min

Test speed: 0.01-100mm/min

Force measurement method: Load sensor measurement

Control test method: The computer automatically controls the test process, and the computer screen displays the test force and test curve, automatically processing the test data according to the requirements of the test method

Specimen clamping method: Customized according to the samples provided by the user

The approximate size of the host (length * width * height) is about: 15000x1550x800mm

Can display a variety of test curves: force-displacement, force-time, force-deformation, stress-strain, etc.

The control panel is separate from the host, with a safe distance, and the host should have safety protection measures.

The configuration should be complete, including a force value calibration system, anchor bolts, etc.