Ceramic Membrane Support Compressive and Flexural Testing Machine

The physical property testing of ceramic membranes is mainly based on national standards such as GB/T 1965-1996, GB/T 1966-1996, GB/T 1967-1996, and GB/T 1968-1996. Specific test items can be selected according to application requirements.

Compression Strength Test: Conducted in accordance with GB/T 1964, measuring the strength of the membrane under compressive load.

Bending Strength Test: Conducted in accordance with GB/T 1965, measuring the strength of the membrane under bending load.

Compressive Strength Test of Ceramic Membranes, Three-Point Bending Determination

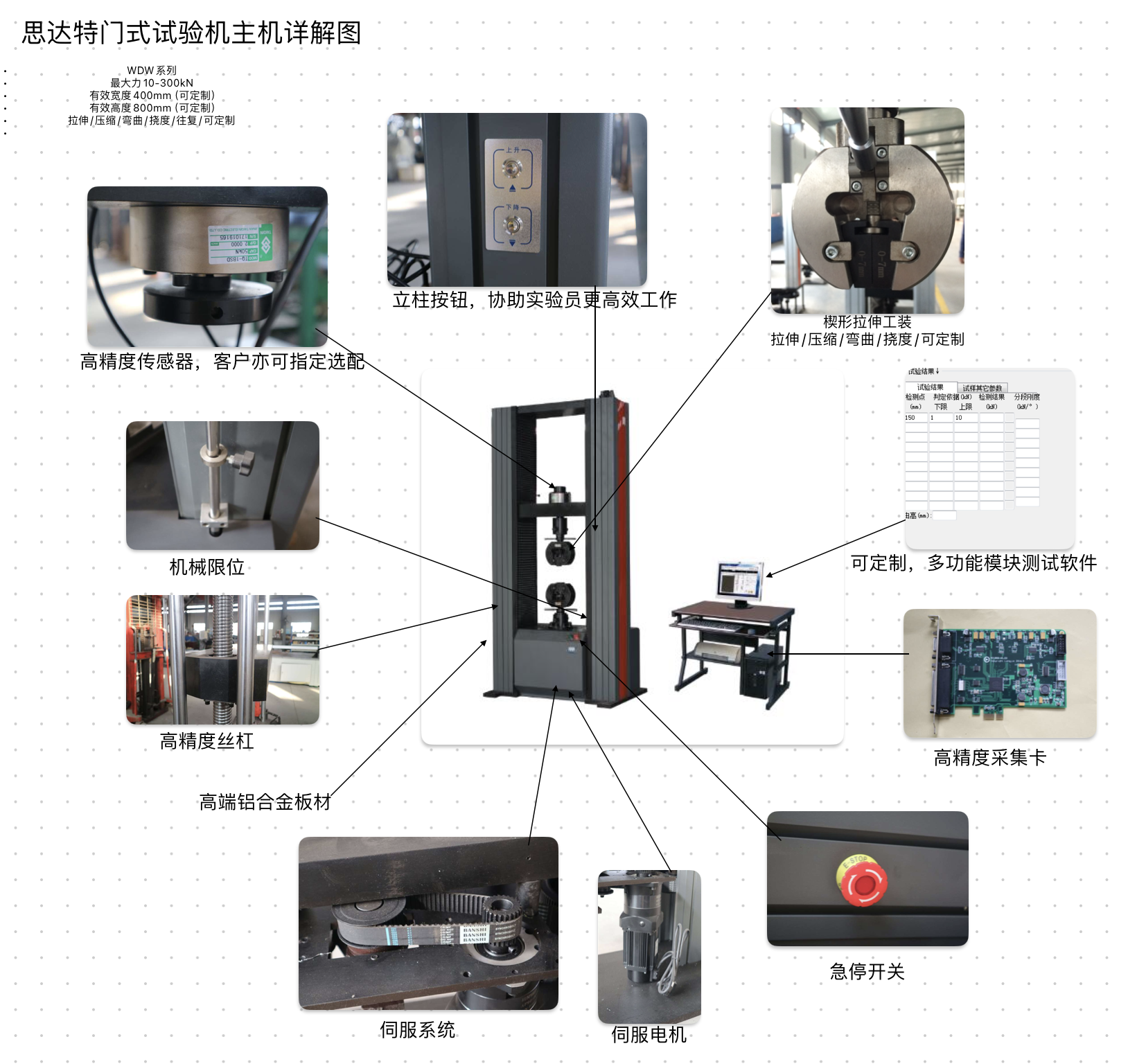

The WDW-10E is a new generation of microcomputer-controlled electronic universal testing machine. It is mainly used for testing the mechanical properties such as tensile, compressive, bending, shearing, peeling, and tearing of various metals, non-metals, and composite materials. The system uses microcomputer closed-loop control, featuring a wide and accurate range of loading speeds and force measurement, with high precision and sensitivity in the measurement and control of load and displacement.

Software Features:

Automatic Stop: The moving crosshead automatically stops when the specimen breaks.

Automatic Gear Shifting (when selecting segmented measurement): The system automatically switches to the appropriate range based on the load size to ensure the accuracy of the measurement data.

Condition Storage: Test control data and specimen conditions can be saved as modules, facilitating batch testing.

Automatic Speed Variation: The speed of the moving crosshead can be automatically varied according to a pre-set program during the test, or it can be manually adjusted.

Automatic Data Saving: Test data and curves are automatically saved after the test is completed.

Process Implementation: The entire testing process, including measurement, display, and analysis, is completed by the microcomputer.

Batch Testing: For specimens with the same parameters, tests can be sequentially completed after a single setup.

Test Software: Chinese Windows interface, menu prompts, and mouse operation.

Dynamic Display: Data and curves are dynamically displayed during the testing process.

Curve Editing: After the test is completed, curves can be re-analyzed, and test data at any point on the curve can be found using the mouse.

Curve Selection: Stress-strain, force-displacement, force-time, displacement-time, and other curves can be selected for display and printing as needed.

Test Report: Reports can be compiled and printed in the format required by the user.

Limit Protection: The system has both programmable and mechanical limit protection.

Overload Protection: The machine automatically stops when the load exceeds 3-5% of the maximum value of each range.

Automatic and Manual Modes: Results can be obtained in both automatic and manual modes, and reports are automatically generated to simplify data analysis.

Technical Parameters:

Maximum Test Force: 10 kN

Testing Machine Accuracy: 0.5 grade

Test Force Measurement Range: 0.4%-100% FS

Test Force Segmentation: 6 segments

Test Force Measurement Accuracy: Better than ±1% of the indicated value;

Displacement Resolution: 0.001 mm;

Displacement Measurement Accuracy: ±1%;

Deformation Measurement Range: 0.2~100%FS;

Deformation Indicated Relative Error: Within ±1%;

Deformation Resolution: 0.001 mm.